Price: $3.92

Good afternoon friends! Not long ago I was puzzled by the next modernization of my home, namely the creation of a remotely controlled LED backlight. Details under the cut)

A short background: I live with my beloved girl, who, despite her 20 full years, second year of medical school with anatomy and other delights and strong nerves, is terribly afraid of the dark. Just to the point of trembling. So much so that the moment between the flick of the switch and the fall of her body into the warm crib with the anti-monster blanket makes her slightly hysterical. I thought that this wouldn’t work and solved the problem ingeniously by ordering the main character of this review.

Meet the load remote control module with an electromagnetic relay and a 433 MHz remote control.

Allows you to control a load of 10 A at a voltage of 250 Volts. "But that's not certain." These are the Chinese. However, I can say with confidence that the relay handled a load of 800-900 W for 2 hours absolutely without problems, I specifically checked it before writing this review. In addition, this relay has been working for me for about a year to control the table lighting, and a similar module with the same relay works in the corridor, controlling the light bulb.

Let's finish with the introduction. Let's start looking at the relay itself.

We see 2 terminal blocks: one for 2 wires and the second for 3 wires. Through the terminal block, 12 volt power is supplied to 2 wires, and the second is used to connect a controlled load. Now let's move on to consider the reverse side of the relay, in particular the connection point of the three-terminal block.

The central contact (COM) serves to connect the input of the open circuit, and the NC and NO contacts, respectively, for the output of the open circuit. In this case, the NC (normal close) contact is closed in the off position of the relay, and the NO (normal open) contact, on the contrary, is open, and when the relay is turned on, they change places. This allows you to turn on or turn off the connected load at the press of a button.

Now let's look at the jumper and understand what it is intended for.

This jumper allows you to change the operating mode of the relay panel, choosing from 3 options.

1) In the case where the jumper is not installed at all: pressing button A closes the relay, and releasing this button opens the relay.

2) A jumper is installed on pins 1 and 2: pressing button A closes the relay, and pressing button B opens the relay.

3) The jumper is installed on contacts 2 and 3: the first press of button A closes the relay, the second press of button A opens the relay, then in a circle.

Now let's look at the button for recording the key fob into memory.

I didn’t have a chance to use it, so I’m quoting the translation from the description on the product page:

1) To record a new key fob, hold the button for 3 seconds and then press the button on the key fob.

2) To clear all recorded keyfobs, hold the button for 8 seconds or more.

As for the range: I can reach about 20 meters through 3-4 concrete walls, and about 50-70 meters in an open area without any problems.

To summarize: I really liked the product, both for its appearance and for the large number of usage scenarios. Now I use such a relay to remotely turn on the lighting in the room (about six months - no problems). In the future I plan to make a remote electric igniter for pyrotechnics based on such a relay. By the way, the current consumption is stated by the seller to be about 6 mAh, but according to my measurements it turned out to be 4 mAh. This will allow you to create autonomous projects based on this relay. Overall, I definitely recommend buying it. Justifies its price.

Good day everyone!!! This time I present to your attention a device for controlling loads using any IR remote control, be it from a TV, DVD player or other household crap :-)

In our progressive times, the variety of circuit designs, the availability of any radio component makes many people so lazy (for example, me) that they are reluctant to get up from the couch once again to even turn on the light. This scheme comes to the aid of such “parasites”. Let me make a reservation right away: the firmware is not mine; before this it was intended for the IR driver and the generation of TxD, RxD signals, etc. I simply modified and also changed circuit diagram, an indicator LED has been added, as well as an executive part in the form of a current-limiting resistor, relays, diodes and transistor switches. Well, I won’t describe much - let’s get started.

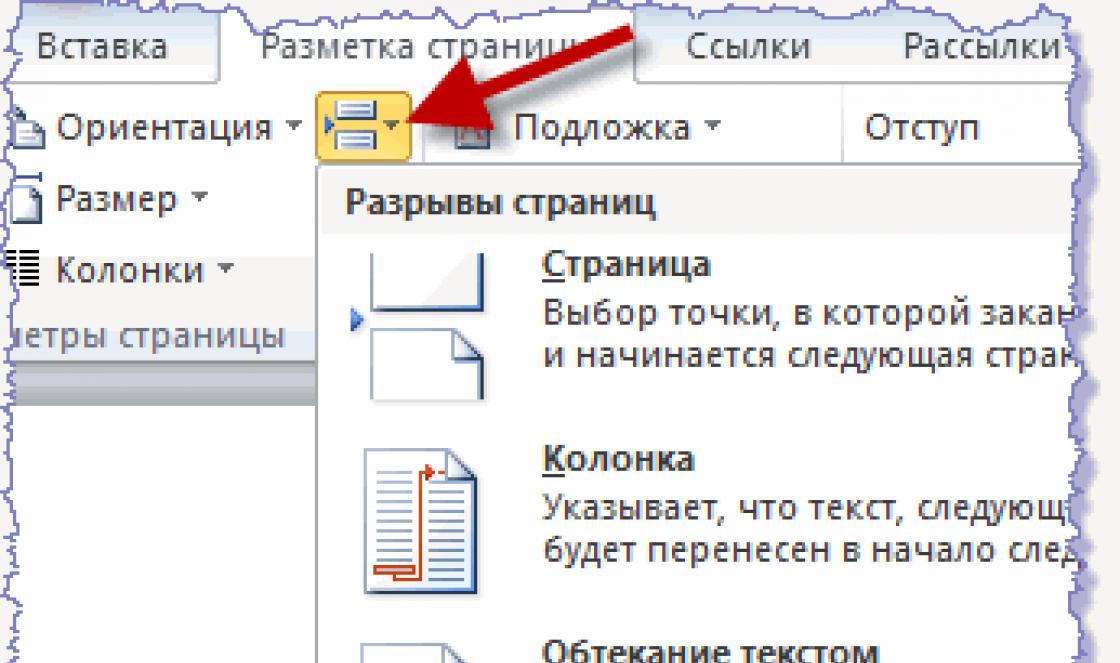

So, the schematic diagram:

As far as you can see, everything is simpler than a steamed turnip :-) For ease of work, I even depicted the pinout of the elements.

The “heart” of this scheme is the cheap and cheerful Attiny13.

Signals from the remote control are received by the integrated IR receiver TSOP4836, a couple of elements in the body kit,

executive part and we get a full-fledged control device for as many as three loads!!!

So, the list of required components:

Let's go get the parts...

And we need the following...

Let's start making scarves, I think this process is not worth describing - nothing new.

As usual: Sprint Layout --> glossy paper --> laser printer--> iron --> water --> acetone --> ferric chloride --> Rose alloy --> drilling --> soldering.

After all the manipulations with the foil PCB and obtaining the “body” we need, we flash the MK.

I really like CodeVisionAVR, so I always work in it. Let's not forget about fuses, namely:

Set the internal RC oscillator to 9.6 MHz (CSKEL = 10)

- Leave the in-circuit programming option enabled (SPIEN = 0)

- Set up EEPROM erasure protection (EESAVE = 0)

- Set the start time to 14 CK + 64 ms(SUT = 10)

For other clarity, I provide a screenshot for CodeVisionAVR

We used a small toroidal transformer to power our lazy device,

which was found in the bins after another search

In appearance, approximately 8-10 watts. Yes, this is quite enough for us.

Even if all loads are turned on, the current consumption will be:

120 µA - microcontroller, 90 mA - 3 relays (I = 12 V / 400 Ohm = 30 mA * 3 = 90 mA)

UUUUU...!!! Yes, this kind of power is enough for us, even too much, but oh well, let’s not be greedy, otherwise the stingy pays twice: fellow:

Just don’t forget to put Tinka on the board after flashing the firmware, otherwise you’ll say later that nothing works

Well, let's hope everything worked the first time for you.

So... let's turn it on

An indicator that the newly flashed internal program launched successfully,

is the blinking of the HL1 LED when power is applied to the circuit. We take any remote control and try to press any button.

If the LED blinks when pressed, this is a sign that the device can work with this remote control.

So far we see that any click does not bring any action. This is all because it does not know the remote control codes, so you need to go through a certain training procedure to do this:

1. Press any button and hold it until the LED goes out (about 10 seconds)

2. Now you need to press 7 keys in sequence, which will be responsible for the commands in the following order:

a) The first button is to turn on the load A

b) Second button - switch on load B

c) The third button is to turn on the load C

d) Fourth button - turn on all loads

e) Fifth button - turn off all loads

f) Sixth button - remembering the current state

g) Seventh button - restore the last remembered state

The codes are stored in non-volatile memory, so this procedure will only need to be performed once.

Now we try to press any of the selected keys. Can we hear the relay clicking? Wonderful!!! Everything worked out :-)

My problem is that I don’t really like making cases, but I have to, so it turned out like this.

Which outputs via UART the code of the key pressed on the IR remote control, it’s not at all difficult to make firmware for direct kicking of the microcontroller’s legs. The only problem is that we don’t know in advance which remote control we will use or which key we will use. We'll have to add a piece to the program that allows us to study necessary buttons. This is what we will do now!

Agree, it’s very convenient when, without getting up from your chair, you can control, in addition to the TV, lighting, a fan or other household appliances in the room with one remote control. What if the device is difficult (or even impossible) to get to? Or you need a remote control to control your model. It is for such purposes that this device is intended. To control the loads, any remote control you choose is suitable, on which you can select any keys. And if suddenly you cannot quickly find the remote control you left somewhere, you can use any other remote control that comes to hand, after going through a simple procedure for studying it. In general, this is a necessary device. Let's collect!

Assembling the device.

For the load control device, let’s take the one we made earlier. There is no need to redo anything - everything we need is already on the board.

The Load A, Load B, Load C legs are designed to control loads (how to connect a load to a microcontroller -). The indicator LED will indicate device activity.

Firmware.

To flash the microcontroller firmware, all the necessary signals are displayed on the board. We connect the programmer and upload the firmware.

- Load control device firmware

- Fuse bits for the device

Device operation.

The device works very simply. Before using the selected remote control, you must go through the procedure of learning it. By pressing the studied buttons on the remote control, you can control the loads: turn them on/off both individually and all together; remember and restore the current state.

Procedure for learning the remote control keys:

— turn on the device;

— for about 10 seconds, hold down any key on the remote control (for different remote controls, the holding time is different, since it is not the holding time that is measured, but the number of auto-repetitions of the button command);

— after 10 seconds, the indicator LED will flicker - the device has entered the learning mode;

— then press the remote control keys sequentially in the order of the device functions. After each key pressed, the device will confirm that the button has been memorized by blinking;

— after the last button learned, the device will confirm the end of learning the remote control with a long flicker and go into load control mode.

You can learn the remote control key commands as many times as you like. The learned buttons are recorded in non-volatile memory, so the device will “remember” them even after the device is de-energized.

The sequence of learning the remote control buttons:

1

turning on/off load A (Load A)

2

turning on/off load B (Load B)

3

turning on/off load C (Load C)

4

turn off all loads

5

turn on all loads

6

save the state of the loads into non-volatile memory

7

restore load state from non-volatile memory

There are 7 teams in total.

If you do not have the required number of free buttons on your remote control, or you do not need some functions, simply press the already learned key on an unnecessary function and this function will not be used.

Video about what it all really looks like:

P.S. This option for processing the IR signal and studying remote controls will be included in the 1W-IR network almost unchanged, i.e. Each device on the network (if it needs it) will be able to receive, in addition to network messages, commands from IR remote controls. The algorithm will still be refined, since it is not yet optimal and has not been debugged.

MODIFICATIONS.

(Changes in some aspects of the device operation. The general operating logic remains the same)

More modifications are possible. You can also show your modifications there.

Modification No. 1.

— Removed: launching the remote control learning procedure when you press any remote key for a long time.

+ Added: launching the remote control learning procedure if crystal pin 6 (PB1) (or board pin Out) is shorted to ground when power is applied. After entering the learning mode (the indicator LED blinks), the leg must be “released”.

Modified firmware Mod1

This type of lighting is actively used in residential, office and even industrial premises. The most popular today are control systems implemented using radio switches, motion sensors, controllers with control panels, smartphones and computers. Modern technologies allow you to manage or on the local area, being hundreds of kilometers away from them. Some of them will be discussed in the article.

Advantage of remote control

The use of remote control devices allows you to solve a number of problems:

- Use energy economically;

- Make the process of turning on/off lamps as comfortable as possible;

- Secure your home or apartment from attacks by intruders (presence effect).

Types of remote control

Remote switching on of light can be wired and wireless, manual and automatic, with the ability to manipulate light from devices operating on the principle of radiation and reception of waves certain frequencies: infrared, microwave, radio frequency, sound, ultrasonic, voice (control of specific commands). In this article we will dwell in detail on lighting control using various types emissions, voice and sound commands.

Infrared and radio wave control of light from the remote control

Infrared lighting control using a remote control is used extremely rarely. Mostly similar systems They work on the principle of transmitting a signal over a radio channel. To be able to manipulate lighting devices using an IR beam, a remote lighting control unit, for example BM8049M, is connected to the open circuit. It allows you to turn on the lamp switch using a regular TV remote control. To do this, point the remote control at the unit, press any key (which is not used to switch channels), after which the command is recorded in memory and now you can control the switching on of the light without getting up from the couch.

The main disadvantages of using IR remote control lights are the need to accurately point them at the signal receiver, since they only work within line of sight, and the short range of the beam, but in this case repeaters can be used.

Light control systems using a remote control have become much more widespread, in which a signal is transmitted from a control device to a controller that regulates the process of turning on/off the light at a certain radio frequency.

Light control via radio is more in demand for several reasons:

- The ability to control the light not only from the remote control, but also from a computer, smartphone and other devices;

- The signal range is about 100 meters in the absence of obstacles, 15-25 meters in the presence of obstacles;

- Possibility of installing signal amplifiers and repeaters for better transmission of commands from the control device.

The lighting remote control system via radio using a remote control consists of:

- Remote control;

- Battery;

- Remote control controller connected to the network and load.

Install the controller into the wall or glass of the chandelier (see photo). It can control incandescent, compact and conventional fluorescent, halogen, LED lamps, and not only with individual lamps, but also with a group of them.

Review of remote lighting control units, made in China, using a remote control, via radio, video:

Remote control of light using infrared and radio switches

Infrared switches are a rarity in the lighting market, as it is smarter to control the light using radio devices. One of the most popular switches is “Sapphire” from Nootekhnika (Belarus). The same company produces many wireless lighting control devices, including those mentioned below. The switch is controlled by any remote control, for example, a television remote control or manually. The signals are received by a receiver located inside the device on touchpad. The light switch with remote control is shown in the photo.

Review of the Sapphire IR switch, video:

Light switch with remote control placed in any place convenient for you, power blocks - in a distribution box or chandelier glass.

An example of “binding” a lighting control unit to a radio switch, video:

Using sensors to control lighting

The lighting equipment market is widely represented various sensors movement, for remote control of lighting. The most common of them are infrared. They are devices that close or open the lighting circuit when the level of infrared radiation increases in their “visibility” zone. As soon as a person or animal whose body temperature is higher than the background temperature enters the sensor’s field of action, the light turns on. As soon as a person leaves the sensor’s coverage area or remains in a stationary position for several seconds, the light turns off. Motion sensors are most often installed in entrances, above the front door, and less often - inside the apartment.

Disadvantages and advantages of infrared sensors

The disadvantages of using motion sensors include the possibility of false alarms (reaction to warm air, sunlight), deterioration of work on the street due to precipitation, failure of the device to operate when a person’s clothing does not transmit infrared radiation, constant turning off of the light after 10-15 seconds as soon as motor activity decreases.

The advantages of sensors include the ability to control electrical energy consumption and, as a result, reduce financial costs, safety for human health, and ease of use.

Connecting motion sensors is not difficult; the installation diagram presented below is very common. To implement it, a three-core wire is required, with which the lighting control device is powered from the network and connected to the load. The phase wire of the network is connected to the phase wire of the sensor. The neutral conductors of the lamp, power supply and sensor are connected together. The lamp is connected with a phase wire to the remaining sensor wire.

Selecting infrared motion sensors

When choosing IR sensors, pay attention to the following parameters:

- Place of application. Sensors are available with degrees of protection from IP20 to IP 55 and are available in built-in and mounted versions. For use in an apartment, a built-in sensor looks more advantageous, and the degree of protection practically does not matter. To install the device on the street or in the entrance, it is better to choose a model with protection from dust and water, mounted on a bracket;

- Maximum range. IR sensors detect changes in background temperature at a distance of 10-20 meters. Those of them that are planned to be installed on the street must have a larger “coverage” radius. Indoors this parameter is of no use;

- Detection angle. In the vertical plane, the viewing angle of the sensors is 15-20 degrees, in the horizontal plane – from 60 to 360 degrees;

- Load power. Before purchasing a sensor, you need to know the power of the load connected to it and select a device based on these indicators with a margin.

Using other motion sensors to control lights

In addition to infrared controllers, microwave, sound and ultrasonic, as well as combined sensors are sometimes used to control lighting.

Microwave sensors

Microwave sensors operate on the principle of emitting and receiving electromagnetic waves. In normal mode, the frequency and length of the waves emitted and reflected from objects are the same. When a person enters the sensor’s coverage area, these parameters change, after which the light circuit switching mechanism is activated. The advantages of microwave sensors are that they are high-precision devices and work well even in bad weather, while the disadvantages are the possibility of false alarms, high price, and harmful radiation for sensors with a large coverage radius.

Ultrasonic sensors

Ultrasonic sensors are similar in operating principle to microwave sensors. Inside these devices there is a generator of sound waves with a frequency of 20 to 60 kilohertz, which are emitted and reflected from objects located in the field of action of the sensor. When a person or animal enters the coverage radius, the frequency of sound waves arriving at the sensor changes, which the device immediately registers. Disadvantages of ultrasonic sensors: they may not respond to smooth movement and cause discomfort in animals. Advantages of sensors: low cost, work in conditions of high humidity, temperature changes, react to movement regardless of what material the person is wearing.

Combined sensors

Combination sensors combine several motion detection technologies. They may use microwave and ultrasonic radiation or infrared and microwave radiation. Such devices perform their assigned tasks most efficiently.

Sound sensors

Sound sensors respond to sudden changes in sound, the level of which is set by changing the sensitivity of the sensor. Most often, the light is turned on and off by clapping your hands. Voice switches can also be considered a type of sound sensors.

Voice control of light

Voice control of lighting devices in an apartment is implemented using voice sensors-switches, often used in systems " Smart home", as well as computers or smartphones on which a special program is installed.

Light switches with remote control (voice) are divided into two types: with the need for adjustment and without it. In the first case, you need to teach the device the commands to activate, turn on and off the light, in the second case, all the commands are already written in memory and indicated in the instructions, you just need to use them for control. Often such switches can be controlled not only by voice, but also by any remote control. These include "Jaco" and "Servi". You can get acquainted with the features of their work on the manufacturers’ websites.

Hi all.

A short review of relays with a 433Mhz radio channel.

There are NC/NO options for connecting one control line

Sometimes you need to turn something on/off remotely, without any 3G/Wi-Fi or cloud services.

For such purposes, it is better to use simple and “clumsy” relays.

The simplest are remote controlled relay modules.

Appearance relay module in the photo.

It's small PCB with a simple relay SONGLE SRD-12VDC-SL-C (3 contacts COM/NO/NC, plus 12V pins per coil), located in a box ala a fuse box.

For control, a small remote control with two buttons (A/B) and an indicator is used.

The AK-RK01SY board contains an LED indicator, a relay and a module wireless communication 433MHz.

Appearance of the control panel

Application options: turning lights on and off, activating an electric lock, opening gates/doors/curtains, remotely turning devices on/off, and so on.

Specifications:

Brand: No Name

Model: AK-RK01SY

Input Power: DC10V-14V

Standby Current:<5MA

RF Frequency: 433MHz

RF working mode: superheterodyne reception

Receive sensitivity: -108dbm

Transmitting distance: 100m (open area)

Decoding mode: MCU software decoding

Working mode: Momentary, Toggle, Latching

Wiring type: fixed terminal

Output Terminal: NO, NC, COM

Remote Control battery: 1*12V 23A (included)

Supporting Remote Control Type: learning code (1527 chip); fixed code

Receiver Board Size: Approx. 3.5*3*3cm

Fuse Box Size: 4*3.7*2.7cm

The parcel arrived quickly, in a postal bag, inside a zip bag with a relay module and a remote control.

Also included was an instruction sheet.

External view of the relay block.

Dimensions almost 4 cm x 4 cm x 2.7 cm

Weight 25 grams is not at all critical, since it implies a stationary installation. Although…

The fuse box case can be easily disassembled; inside there is simply a board with a relay and a receiver.

The sizes are also small

On the reverse side there is a pinout of the block, as well as a reminder marking about the operating modes.

The antenna is in the form of a spiral of wire, the receiver module is soldered vertically to the relay board

Assembled.

The remote control for the relay module is small, convenient to carry on your keys as a key fob

Weight only 20 grams

On the back side there is a sticker with the frequency of the remote control range.

Let's disassemble the remote control

Inside there is a 12V battery of size 23A (as in car alarms), as well as a board with two buttons and a radio transmitter

The battery itself is comparable in cost to the entire relay module. The fact that it already exists is a big plus.

Marking of the printed circuit board of the AK-BF02 remote control

The transmitter is assembled based on the NDR4208 resonator (received frequency is about 433.92 MHz)

Well, two microbuttons A and B, respectively. As well as an LED indicating operation.

Reverse side without elements. It is noteworthy that there is a footprint for one chip and on the reverse side for coding (an array of HLF jumpers). In this version, all this is not used.

The work is simple. We connect according to the above diagrams into the open circuit of the power supply of the actuator.

We press the buttons on the remote control. Please note that during transmission from the remote control there is an indication (red LED).

Button A made of red transparent plastic. IN- from gray

Once again, the reverse side of the remote control - everything is held on by two screws

Photo in hand. The remote control is really like a keychain, small.

Of the important things, here is a description of the remote control training modes:

Operating modes: Momentary, Toggle and Latched.

1. Press the Learn button on the board once. We are waiting for the diode to blink. Press the button on the remote control. The diode flashes again and the operating mode is set to “1” - Instant.

It serves to activate the device while holding the button. Conventionally, we hold the button on the remote control and the backlight is on.

2. Press the Learn button on the board 2 times. We are waiting for the diode to blink. Press the button on the remote control. The diode flashes again and the operating mode is set to “2” - Switching.

Presses a button on the remote control - the device turns on. Press the same button again - the device turns off.

3. Press the Learn button on the board 3 times. We are waiting for the diode to light up. Press button A on the remote control. The diode on the board blinks. Then press button B on the remote control. The diode flashes again and goes out.

Now the device will be turned on only by button A, and turned off by button B.

The most convenient mode for me))))

Additional information - instructions in English

A universal way to connect to the power supply circuit of a controlled device

Another connection example: A) 12V power supply for lighting (for example, LED strips), and B) 220V power supply for light bulbs (suitable for controlling any load, 1V.....250V, up to 10A).

I connect the relay module for testing.

In the photo, LED indication during training

Several tests

In idle mode, consumption is minimal - about 0.002A.

When triggered and held, the current increases. About 0.05A.

Instant mode. I press and hold A- the light is on. I let go and it immediately goes out.

Hold mode. I press A and when I release it, the light comes on and stays on. The relay is always on. I press IN and let go - it goes out.

At first I thought about putting it in the 3D printer's power supply as a backup button.

But a problem arose with the power of the heated table.

Naturally, such a connection is not effective.

Converted it to separate power supply for the table and the rest of the electronics.

From the power supply 6A goes through this relay module and I can turn off the printer control and nozzle/motor heating using a button.

The table is heated through a solid state relay. Accordingly, if the control board is de-energized, then the table does not heat up.

Quite convenient, especially when monitoring within a room/apartment. If someone at home starts screaming that there’s a cobweb again or something else, then you can always turn it off from the key fob without taking out your smartphone and without frantically searching for the cloud control button.

Overall the relay is convenient. Small size and universal connection allow you to control anything.

Two points are important: control is used at a frequency of 433 MHz, that is, you can control another similar relay module with a similar frequency, as well as select a remote control for your module if it is lost.

The second point is that the remote control range is stated to be no more than 100m (without interference). I worked within the apartment - it works fine. If you open a lock or gate while standing directly in front of it, there is also no problem. At a glance - 20 meters works. I have not checked the maximum operating range. Again, this very much depends on the battery level.

The product was provided for writing a review by the store. The review was published in accordance with clause 18 of the Site Rules.

I'm planning to buy +37 Add to favorites I liked the review +45 +71