Liquid crystal monitor (also liquid crystal display, LCD, LCD monitor, English liquid crystal display, LCD, flat display) is a flat monitor based on liquid crystals. LCD monitors were developed in 1963.

LCD TFT (English TFT - thin film transistor - thin film transistor) is one of the names for a liquid crystal display that uses an active matrix controlled by thin film transistors. Amplifier TFT for each subpixel is used to improve the performance, contrast and clarity of the display image.

LCD monitor device

The image is formed using individual elements, usually through a scanning system. Simple devices(electronic watches, phones, players, thermometers, etc.) can have a monochrome or 2-5 color display. A multicolor image is formed using RGB triads. Most desktop monitors based on TN (and some *VA) panels, and all laptop displays use 18-bit color matrices (6 bits per channel), 24-bit emulated flickering with dithering.

Subpixel of color LCD display

Each pixel of an LCD display consists of a layer of molecules between two transparent electrodes, and two polarizing filters, the planes of polarization of which are (usually) perpendicular. In the absence of liquid crystals, the light transmitted by the first filter is almost completely blocked by the second.

The surface of the electrodes in contact with the liquid crystals is specially treated to initially orient the molecules in one direction. In a TN matrix, these directions are mutually perpendicular, so the molecules, in the absence of tension, line up in a helical structure. This structure refracts light in such a way that the plane of its polarization rotates before the second filter, and light passes through it without loss. Apart from the absorption of half of the unpolarized light by the first filter, the cell can be considered transparent. If voltage is applied to the electrodes, the molecules tend to line up in the direction of the field, which distorts the screw structure. In this case, elastic forces counteract this, and when the voltage is turned off, the molecules return to their original position. With a sufficient field strength, almost all molecules become parallel, which leads to an opaque structure. By varying the voltage, you can control the degree of transparency. If a constant voltage is applied for a long time, the liquid crystal structure may degrade due to ion migration. To solve this problem, alternating current is used, or changing the polarity of the field with each addressing of the cell (the opacity of the structure does not depend on the polarity of the field). In the entire matrix, it is possible to control each of the cells individually, but as their number increases, this becomes difficult to achieve, as the number of required electrodes increases. Therefore, row and column addressing is used almost everywhere. The light passing through the cells can be natural - reflected from the substrate (in LCD displays without backlight). But more often an artificial light source is used; in addition to independence from external lighting, this also stabilizes the properties of the resulting image. Thus, a full-fledged LCD monitor consists of electronics that processes the input video signal, an LCD matrix, a backlight module, a power supply and a housing. It is the combination of these components that determines the properties of the monitor as a whole, although some characteristics are more important than others.

LCD Monitor Specifications

Permission: Horizontal and vertical dimensions expressed in pixels. Unlike CRT monitors, LCDs have one, “native” physical resolution, the rest are achieved by interpolation.

Point size: Distance between the centers of adjacent pixels. Directly related to physical resolution.

Screen aspect ratio(format): Width to height ratio, for example: 5:4, 4:3, 5:3, 8:5, 16:9, 16:10.

Visible diagonal: The size of the panel itself, measured diagonally. The area of displays also depends on the format: a monitor with a 4:3 format has a larger area than one with a 16:9 format with the same diagonal.

Contrast: Ratio of brightness of the lightest and darkest points. Some monitors use an adaptive backlight level using additional lamps; the contrast figure given for them (the so-called dynamic) does not apply to a static image.

Brightness: The amount of light emitted by a display, usually measured in candelas per square meter.

Response time: The minimum time it takes for a pixel to change its brightness. Measurement methods are controversial.

Viewing angle: angle at which the drop in contrast reaches a given value, for different types matrices and different manufacturers are considered differently, and often cannot be compared.

Matrix type: The technology used to make the LCD display

Inputs: (eg DVI, D-SUB, HDMI etc.).

Technologies

Key technologies in the manufacture of LCD displays: TN+ film, IPS And MVA. These technologies differ in the geometry of the surfaces, polymer, control plate and front electrode. The purity and type of polymer with liquid crystal properties used in specific designs are of great importance. Response time of LCD monitors designed using SXRD (Silicon X-tal Reflective Display)- silicon reflective liquid crystal matrix), reduced to 5 ms. Sony companies, Sharp and Philips jointly developed PALC technology. Plasma Addressed Liquid Crystal- plasma control of liquid crystals), which combines the advantages LCD(brightness and richness of colors, contrast) and plasma panels (large viewing angles along the horizon, H, and vertical, V, high update speed). These displays use gas-discharge plasma cells as brightness control, and an LCD matrix is used for color filtering. PALC technology allows each display pixel to be addressed individually, meaning unrivaled controllability and image quality.

TN+ film (Twisted Nematic + film)

Macro photography TN+ film NEC LCD1770NX monitor matrix. On a white background is a standard Windows cursor.

Part " film" in the name of the technology means an additional layer used to increase the viewing angle (approximately from 90° to 150°). Currently, the prefix " film" is often omitted, calling such matrices simply TN. Unfortunately, a way to improve the contrast and response time for TN panels has not yet been found, and the response time is of this type matrices is currently one of the best, but the contrast level is not.

Matrix TN+ film It works like this: If no voltage is applied to the subpixels, the liquid crystals (and the polarized light they transmit) rotate 90° relative to each other in the horizontal plane in the space between the two plates. And since the polarization direction of the filter on the second plate makes an angle of 90° with the polarization direction of the filter on the first plate, light passes through it. If the red, green and blue sub-pixels are fully illuminated, a white dot will appear on the screen.

IPS (In-Plane Switching)

In-technology Plane Switching was developed by Hitachi and NEC and was intended to get rid of the shortcomings of TN + film. However, although IPS was able to increase the viewing angle to 170°, as well as high contrast and color reproduction, the response time remained at a low level.

If no voltage is applied to the IPS matrix, the liquid crystal molecules do not rotate. The second filter is always turned perpendicular to the first, and no light passes through it. Therefore, the display of black color is close to ideal. If the transistor fails, the “broken” pixel for the IPS panel will not be white, as for the TN matrix, but black.

When voltage is applied, the liquid crystal molecules rotate perpendicular to their initial position and transmit light.AS-IPS - Advanced technology Super IPS(Advanced Super-IPS), was also developed by Hitachi Corporation in 2002. The improvements mainly concerned the contrast level of conventional S-IPS panels, bringing it closer to the contrast of S-PVA panels. AS-IPS is also used as the name for NEC monitors (for example NEC LCD20WGX2) created using S-IPS technology developed by the LG.Philips consortium.

A-TW-IPS - Advanced True White IPS (Advanced IPS with True White), developed by LG.Philips for NEC Corporation. It is an S-IPS panel with a TW (True White) color filter to make the white color more realistic and expand the color range. This type of panel is used to create professional monitors for use in darkrooms and/or publishing houses.

AFFS- Advanced Fringe Field Switching(unofficial name S-IPS Pro). The technology is a further improvement of IPS, developed by BOE Hydis in 2003. The increased power of the electric field made it possible to achieve even greater viewing angles and brightness, as well as reduce the interpixel distance. AFFS-based displays are mainly used in tablet PCs, on matrices manufactured by Hitachi Displays.

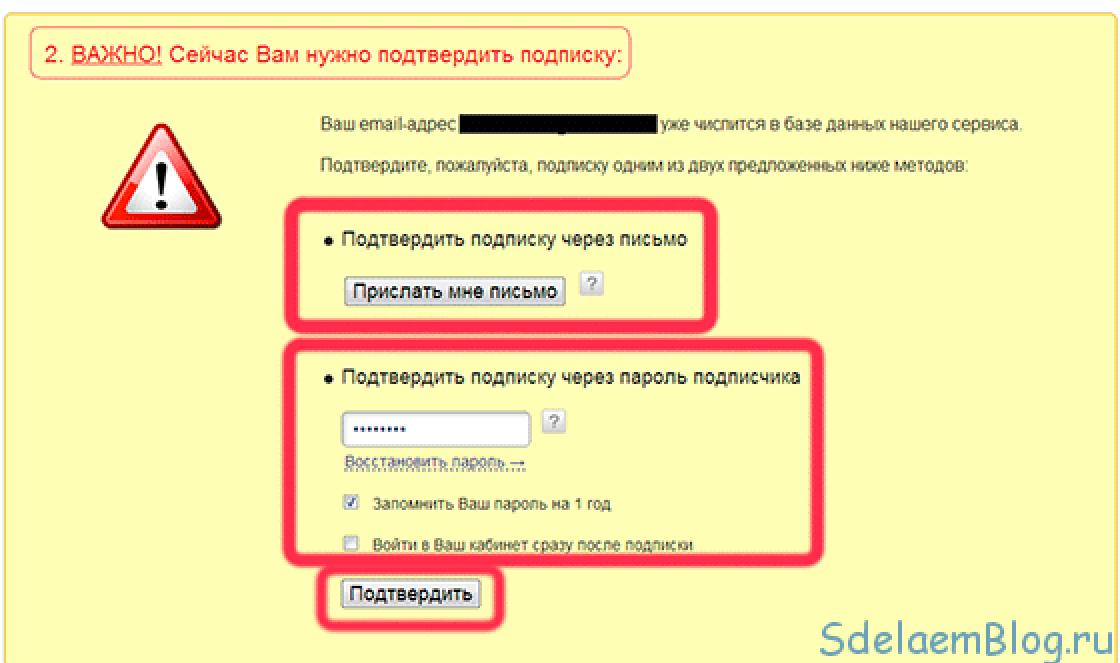

Nowadays, technology does not stand still; it is rapidly developing, thanks to which more and more new, amazing and high-tech devices are coming into the world. This also applies to manufacturing technologies for LCD monitors, which today are most widespread and have the greatest prospects. But what is the design of an LCD monitor and what are its advantages? This is exactly what will be discussed in this publication.

1. What is an LCD monitor

First, it’s worth understanding what an LCD monitor is. To do this, you need to understand what an LCD display is. As you probably already guessed, LCD is a kind of abbreviation, the full name is as follows - Liquid Crystal Display. Translated into Russian, this means liquid crystal display. Thus, it becomes clear that LCD and LCD are the same thing.

This technology is built on the use of special liquid crystal molecules that have unique properties. Such monitors have a number of undeniable advantages. In order to understand them, it is worth examining in more detail the principle of operation of LCD monitors.

2. The design of an LCD monitor and the principle of its operation

As mentioned above, special substances called cyanophenyls are used to make an LCD display. They are in a liquid state, but at the same time they have unique properties that are inherent in crystalline bodies. In essence, it is a liquid that has anisotropy of properties, in particular optical ones. These properties are associated with order in the orientation of molecules.

The operating principle of liquid crystal monitors is based on the polarization properties of crystal molecules. These molecules are capable of transmitting exclusively that component of light whose electromagnetic induction vector is located in a parallel optical plane of the polaroid (crystal molecule). Crystals do not transmit other light spectrums. In other words, cyanophenyls are light filters that transmit only a certain spectrum of light - one of the primary colors. This effect is called polarization of light.

Due to the fact that long molecules of liquid crystals change their location depending on the electromagnetic field, it has become possible to control polarization. That is, depending on the strength of the electromagnetic field acting on cyenophenyls, they change their location and shape, thereby changing the angles of refraction of light and changing their polarization. It is thanks to the combination of the electro-optical properties of crystals and the ability to take the shape of a vessel that such molecules are called liquid crystals.

It is on these properties that the principle is based LCD operation monitor. Due to changes in the strength of the electromagnetic field, the liquid crystal molecules change their position. Thus, an image is formed.

2.1. LCD matrix

The matrix of LCD monitors is an array consisting of many tiny segments called pixels. Each of these pixels can be controlled individually, resulting in a specific picture. The LCD monitor matrix consists of several layers. The key role is played by two panels, which are made of sodium-free and absolutely pure glass material. This material is called substrate (or popularly – substrate). It is between these two layers that the thinnest layer of liquid crystals is located.

In addition, the panels have special grooves that control the crystals, giving them the desired orientation (position). These grooves are located parallel to each other on the panel and perpendicular to the location of the grooves on the other panel. That is, on one panel they are horizontal, and on the other they are vertical. If you look at the screen through a magnifying glass, you will be able to see the thinnest stripes (vertically and horizontally). They form small squares - these are pixels. They come in round shapes, but the vast majority are square.

Illumination of liquid crystal panels can be implemented in two ways:

- Reflection of light;

- Passage of light.

In this case, the plane of polarization of light fluxes can be rotated by 90˚ at the moment of passing through one panel.

In the event of an electric field, the crystal molecules are partially aligned vertically along this field. In this case, the angle of rotation of the plane of polarization of light fluxes changes and becomes different from 90˚. Thanks to this, light passes through the molecules unhindered.

Such a rotation of the plane is absolutely impossible to notice with the naked eye. Because of this, there was a need to add two other layers to the glass panels, which act as polarizing filters. They transmit exclusively those spectra of light rays whose polarization axis corresponds to the set value. In other words, thanks to the additional panels, the moment the light passes through the polarizer, it will be weakened. The light intensity depends on the angle between the polarization plane (additional panels) and the polarizer axis (main glass panels).

If there is no voltage, then the cell will be completely transparent, since the first polarizer is exclusively light that has the corresponding polarization direction. The direction of polarization is set by the liquid crystal molecules, and by the time the light reaches the second polarizer, it will already be rotated to pass through it without difficulty.

In the case of exposure to an electric field, the polarization vector is rotated to a smaller angle. This in turn makes the second polarizer partially transparent to light streams. If we make it so that there is no rotation of the plane of polarization in liquid crystal molecules, then the light will be completely absorbed by the second polarizer. In other words, when the back of the display is illuminated, the front will swing completely black.

2.2. Polarization control in LCD monitors using electrodes

Taking this into account, the developers have equipped the displays with a sufficient number of electrodes that create different electromagnetic fields in individual parts of the screen (in each pixel). Thanks to this solution, they achieved the ability, under conditions of proper control of the potentials of these electrodes, to reproduce letters and even complex multi-colored pictures on the display screen. These electrodes can have any shape and are located in transparent plastic.

Thanks to modern innovations in technology, electrodes are very small in size - they are practically invisible to the naked eye. Thanks to this, a fairly large number of electrodes can be placed on a relatively small display area, which makes it possible to increase the resolution of the LCD display. This in turn allows you to improve the quality of the displayed image and reproduce even the most complex images.

2.3. Obtaining a color image

The operating principle of liquid crystal monitors involves rather complex processes. However, thanks to this, the user receives high quality images on his monitor. In order to display color images, an LCD display requires a backlight, which allows light to come from the back of the screen. This allows users to experience the highest possible image quality, even in dark environments.

The operating principle of LCD monitors for displaying color images is based on the use of the same three primary colors:

- Blue;

- Green;

- Red.

To obtain these spectra, three filters are used to filter out the remaining spectra of visible radiation. By combining these colors for each pixel (cell), it is possible to display a full color image.

Today there are two ways to obtain a color picture:

- Using several filters located one after another. This results in a small fraction of transmitted light.

- Using the properties of liquid crystal molecules. To reflect (or absorb) radiation of the required length, you can change the strength of the electromagnetic field voltage, which affects the arrangement of liquid crystal molecules, thereby filtering the radiation.

Each manufacturer chooses its own option for obtaining a color image. It is worth noting that the first method is simpler, but the second is more effective. It is also worth noting that to improve image quality in modern LCD displays that have high screen resolution, STN technology is used, which allows you to rotate the polarization planes of light in crystals by 270˚. Such types of matrices as TFT and IPS have also been developed.

It is TFT and IPS matrices that are most widespread nowadays.

TFT stands for Thin Film Transistor. In other words, it is a thin-film transistor that controls the pixel. The thickness of such a transistor is 0.1-0.01 microns. Thanks to this technology, it is possible to achieve even higher image quality by controlling each pixel.

IPS technology is the latest development that allows you to achieve the highest image quality. It provides maximum viewing angles, but has a longer response time. That is, it reacts more slowly to voltage changes. However, the time difference between 5 ms and 14 ms is absolutely not visible.

Now you know how an LCD monitor works. However, that's not all. There is such a thing as screen refresh rate.

3. LCD monitor refresh rate

Screen refresh rate is a characteristic that indicates the number of possible image changes per second - the number of frames per second. This indicator is measured in Hz. The screen refresh rate affects image quality, in particular the smoothness of movements. The maximum visible frequency limit is 120 Hz. We will not be able to see a frequency above this limit, so there is no point in increasing it. However, in order for the monitor to operate at such a frequency, a powerful video card is needed that can produce the same 120 Hz with a margin.

In addition, the screen refresh rate affects the visual organs and even the psyche. This effect is expressed primarily on eye fatigue. With a low flicker frequency, the eyes quickly get tired and begin to hurt. In addition, seizures can be caused in people prone to epilepsy. However, modern LCD monitors use special lamps to backlight the matrix, which have a frequency of over 150 Hz, and the indicated refresh rate has a greater effect on the speed of the picture change, but not on the flickering of the display. Therefore, LCD monitors have the least impact on the visual organs and the human body.

4. How LCD display works: Video

4.1. Required monitor frequency for 3D viewing

To use active and polarized 3D glasses, LCD matrices are used with a screen refresh rate of 120 Hz. This is necessary in order to separate the images for each eye, and the frequency for each eye must be at least 60 Hz. Monitors with a frequency of 120 Hz can be used for regular 2D movies or games. At the same time, the smoothness of movements is noticeably better than in monitors with a frequency of 60 Hz.

In addition, such monitors use special lamps or LED backlights that have an even higher flicker frequency, which is about 480 Hz. This in turn significantly reduces the load on the visual organs.

In modern monitors you can find two methods of implementing matrix backlighting:

- LED – LED backlight;

- Fluorescent lamps.

All major manufacturers are switching to the use of LED backlighting, as it has significant advantages over fluorescent lamps. They are brighter, more compact, more economical and allow for a more uniform light distribution.

Thanks to the use of the latest technologies, LCD monitors are absolutely not inferior to their direct competitors - plasma panels, and in some cases even surpass them.

Let's look at the design of an LCD module for a 19-inch monitor using the example of an LCD module with a TN+Film matrix from the well-known Taiwanese manufacturer HannStar. These modules were used in monitors under the brands Acer, LG, HP, etc.

Under the protective metal cover there are matrix controls located on one board.

through the connector designated CN1, LVDS low-voltage differential signaling signals and +5V supply voltage are supplied to the matrix control board

The controller is responsible for processing LVDS signals from the scaler on the matrix control board

the controller generates signals that, through decoders fused into the cables, control the TFT (Thin film transistor) field-effect transistors of the subpixels of the matrix

in the following image you can see how the subpixels of the matrix are located, alternating in order R-G-B(red-green-blue)

the liquid crystals of each subpixel are controlled separately field effect transistor, that is, in a matrix with a resolution of 1280x1024 there are 1280x1024 = 13010720 pixels, and each pixel in turn consists of three subpixels, thus, the number of transistors in a matrix with a resolution of 1280x1024 is 3932160.

Without going into details of the polarization of the light flux, in a simplified way, you can imagine in general how the LCD matrix works like this: if you apply voltage to the subpixel transistor, then the subpixel will NOT transmit light, if you do not apply voltage, the subpixel will transmit light. If all three RGB subpixels transmit light, then we will see a white dot (pixel) on the screen; if all three subpixels do NOT transmit light, then we will see a black dot on the screen. Depending on the intensity of the light flux (i.e., on the angle of rotation of the liquid crystals in the subpixel) passing through three RGB filters of one pixel, we can get a point of any color

A converter made on the U200 integrated circuit is responsible for generating the necessary supply voltages for the TFT matrix.

If you remove the metal frame and separate the LCD matrix from the reflector/light guide, you will find that the matrix is almost transparent

Let's look at the design of the light guide/diffuser. a plastic frame fixes three films (two scattering and one polarizing between them) on the surface of the light guide, which is a rectangular plexiglass plate ~10mm thick

under the light guide there is a white plastic substrate, 0.5 mm thick

on the side of the light guide facing the white plastic substrate, a special pattern is applied to create uniform illumination at all points of the display

The final piece of the diffuser/light guide “pie” is a metal base; this base contains fastening elements with which the entire LCD module is fixed in the monitor body

high-voltage gas-discharge CCFL (Cold cathode fluorescent lamps) lamps are located in twos, horizontally above and below the light guide

The reflector is several millimeters longer than the larger side of the light guide plate and also serves as a container, thanks to which the lamps are fixed at the top and bottom of the light guide

Thanks to the special pattern of the light guide, the light of the lamps is distributed evenly over the entire area of the screen. There are other diffuser designs without a heavy light guide plate, and lamps located horizontally from top to bottom with a single pitch behind the LCD matrix. There are diffuser/light guide (backlight) designs using a larger number of lamps, for example 6, 8, 12

Important!

This material is intended for informational purposes only. If you do not have sufficient experience in restoring LCD devices, do not disassemble your monitor; as a result of incorrect actions, you may damage the LCD module

Most modern LCD monitors have a fairly simple design if we consider it at the chip level, i.e. in the monitor we now see two or three large microcircuits. The functional purpose of these microcircuits in most cases is standard, despite the fact that they are produced by different manufacturers and have different markings. And since the microcircuits perform the same functions, their input/output signals will be almost identical, i.e. The main difference between the microcircuits lies in their characteristics and the pinout of the case. That is why most modern LCD monitors, despite their many brands and many different models, can use the same approaches when diagnosing faults and repairing them. In addition to the identical functional diagram, almost all LCD monitors have the same layout, i.e. Almost all manufacturers have come to the same scheme for distributing the electronic components of the monitor across various printed circuit boards.

So, if you look at a modern LCD monitor, then inside it we will usually find the LCD panel itself and three printed circuit boards(Fig. 1):

Fig.1

- main control and signal processing board (Main PCB);

- power supply and backlight inverter board (Power PCB);

- front control panel board.

Interblock connections with this monitor layout are shown in Figure 2.

Fig.2

Many modern monitors can be used as a USB hub to which various USB devices. Therefore, the monitor may include another printed circuit board corresponding to the USB hub, but the presence of this board is, of course, optional.

The main control board houses the monitor microprocessor and scaler. This board processes monitor input signals and converts them into LCD panel control signals. This particular board largely determines the quality of the image reproduced on the monitor screen. The main difference between monitor models is the configuration of this printed circuit board, the type of microcircuits installed on it and their firmware.

The front control panel board is a narrow printed circuit board containing only buttons and an LED.

The power supply board (in LG documentation it is referred to as LIPS) is a combined power supply that consists of two switching converters: the main power supply and the backlight inverter. This board generates all the main voltages necessary for the operation of both the main board and the LCD panel, and also generates high voltage for backlight lamps. It is this printed circuit board that causes the greatest number of different problems and failures of LCD monitors.

But there is a second layout option, in which, in addition to the LCD matrix, the monitor has four printed circuit boards:

- main control and signal processing board (Main PCB);

- power supply board (Power PCB);

- backlight inverter board (Back Light Inverter PCB);

- front control panel board.

In this layout option, the power supply and backlight inverter are separate printed circuit boards (Fig. 3).

Fig.3

Interblock connections characteristic of this monitor layout are presented in Fig. 4. As an example, we can present the LG FLATRON L1810B and L1811B monitors.

Fig.4

Before talking about the various circuit design options for LCD displays, let's give a brief description of the main components they consist of.

Microprocessor

Microprocessor, which in various sources may be referred to as CPU, MCU And MICOM, general control of the monitor is carried out. Its main functions are:

- generation of signals to turn on and off the backlight;

- control of the brightness of backlight lamps;

- setting the operating mode of the scaler;

- generation of signals that control the operation of the scaler;

- processing and control of input clock signals HSYNC and VSYNC;

- determination of the monitor operating mode;

- type definition input interface(D-SUB or DVI);

- processing of signals from the front control panel.

The microprocessor's control program, as a rule, is located in its internal ROM, i.e. This program is “hardwired” into the microprocessor. However, part of the control code, and especially various data and variables, is stored in external non-volatile memory, which is an electrically reprogrammable ROM - EEPROM. The microprocessor has direct access to the EEPROM chips.

The microprocessor is typically 8-bit and runs on clock speeds about 12 – 24 MHz. The microprocessor, in fact, is a single-chip microcontroller, which, in addition to the CPU, also contains:

- multi-purpose digital input/output ports with programmable functions;

- analog input ports and digital-to-analog converter;

- clock generator;

- ROM;

- RAM and other elements.

EEPROM

Non-volatile memory primarily stores data about monitor settings and user-specified settings. This data is retrieved from the EEPROM when the monitor is turned on and the microprocessor is initialized. Each time you adjust the monitor and set a new custom value for any image parameter, these new values are written to the EEPROM, allowing you to save them. In modern monitors, chips with serial bus access are mainly used as EEPROM I2C(signals S.D.A. And SCL). These are chips like 24C02, 24C04, 24C08 etc.

DDC-EEPROM

All modern monitors support Plug&Play technology, which involves transferring passport and configuration information about the monitor from the monitor to the PC. To transmit this data, the DDC serial interface is used, to which the signals on the interface correspond DDC-DATA (DDC-SDA) And DDC-CLK (DDC-SCL). The passport information itself is stored in another EEPROM, which is practically directly connected to the interface connector. The same chips are used as EEPROM 24C02, 24C04, 24C08, and a more specialized one can also be used - 24C21.

Driver RESET

The RESET signal generation circuit provides control of the microprocessor supply voltage. If this voltage falls below the permissible value, the operation of the microprocessor is blocked by setting the REST signal to a low level. A Low Drop stabilizer chip, such as KIA7042 or KIA7045, is most often used as a signal conditioner.

Scaler

The scaler chip processes signals coming from the PC. A scaler in most cases is a multifunctional microcircuit, which usually includes:

- microprocessor;

- TMDS receiver (receiver), which provides reception and conversion into parallel form of data transmitted via the DVI interface;

- analog-to-digital converter - ADC (ADC), which converts input analog signals R/G/B;

- PLL block, which is necessary for correct analog-to-digital conversion and synchronous signal generation at the ADC output;

- scaling circuit (Scaler), which provides conversion of an image with an input resolution (for example, 1024x768) into an image with the resolution of an LCD panel (for example, 1280x1024);

- OSD driver;

- transmitter (LVDS), which converts parallel color data into serial code transmitted to the LCD panel via the LVDS bus.

In addition to these basic elements, some scalers also include a gamma correction circuit, an interface for working with dynamic memory, a frame grabber circuit, format conversion circuits (for example, YUV to RGB), etc.

In fact, the scaler is a microprocessor optimized for performing very specific tasks - image processing. The scaler is adjusted to the format of the input signals, receiving appropriate commands from central processor monitor.

If your monitor has a frame buffer ( RAM), then working with it is a function of the scaler. For this purpose, many scalers are equipped with an interface for working with dynamic memory.

An example of a functional diagram of the GM5020 scaler used in the LG FLATRON L1811B monitor is presented in Fig. 5. A special feature of this scaler is that it does not contain an internal LVDS transmitter, and generates color signals in the form of a parallel 48-bit digital data stream. When using the GM5020 scaler, an external LVDS transmitter, which is a specialized chip, is also required.

Fig.5

Frame buffer

A frame buffer is a random access memory of sufficiently large capacity, which is used to save an image of an image displayed on the screen. This memory is required when converting (scaling) the image, i.e. when the input resolution does not match the resolution of the LCD panel. Dynamic memory, most often SDRAM, is used as a frame buffer. The capacity of this memory is determined by the developer, based on the format of the LCD panel and its color characteristics.

DC-DC converter

This module ensures the formation of all constant voltages necessary for the operation of the monitor. These voltages are: +5V, +3.3V, +2.5V or +1.8V. The converters are either linear or pulsed DC voltage converters.

Clock Buffer

Clock buffers are amplifiers made either on transistors or on small logic chips. The buffer provides amplification and buffering of the HSYNC and VSYNC input synchronization signals. Often the buffers are controlled by a microprocessor, which allows you to select the signal source, as well as select the type of synchronization (separate, composite or SOG).

Inverter

The inverter generates high-voltage and high-frequency voltage for the backlight lamps. It is a pulsed high-frequency converter that creates +12V voltage impulse voltage amplitude about 800V.

power unit

The power supply generates DC voltages +12V and +5V from the alternating mains voltage, which are used to power all stages of the monitor. The power supply is switching and can be used as an external network adapter, and the internal monitor module, although in the monitors presented in this review, the power supply is internal.

The vast majority of LCD monitors can be classified into one of three basic circuit design options, which we will try to characterize.

1) First option characterized by the presence of two main chips on the MAIN BOARD: a microprocessor chip and a scaler chip. The microprocessor carries out general control of the monitor components, and the scaler converts color signals, i.e. adjusts the image to the resolution of the LCD panel. In this case, the scaler processes the data “on the fly”, i.e. without first storing the image image in intermediate memory. Therefore, memory chips are not used in this version of the circuit design. The block diagram of such an LCD monitor is shown in Fig. 6.

Fig.6

2) Second option (Fig. 7) differs from the first one in the presence of memory chips in the monitor, which are often called a frame buffer. The presence of memory chips is typical for higher-class monitors that are capable of working with images of various input formats, including television. This class of monitors mostly includes 18-inch monitors, for example FLATRON L1811B.

Fig.7

3) Third option characterized by the presence of only one “active” chip on the main board MAIN BOARD. By the term "active microcircuit" we mean a microcircuit that has its own command system, is programmable to perform various functions and is capable of performing some kind of signal processing. In some monitors (for example, in FLATRON L1730B and L1710S), we see only one such chip, which combines both the functions of a microprocessor and the functions of a scaler. Since such microcircuits can be used in various models monitors, and since the microcircuit contains a microprocessor, the operation of which requires the presence of control codes, then on the MAIN BOARD board we will also find a read-only memory chip - ROM (ROM). This chip, which is most often an 8-bit parallel access ROM, contains the control program for operating the combined scaler-microprocessor chip. Often the ROM chip is electrically reprogrammable and is therefore often referred to as FLASH. Almost all LG monitors use the AT49HF family microcircuit as ROM. A block diagram of monitors with such circuitry is shown in Fig. 8.

Fig.8

In addition to these three options for constructing a monitor, you can enter one more option. It differs in that the monitor uses a scaler that does not have a built-in LVDS transmitter. In this case, the transmitter corresponds to a separate chip, which is installed on the main board between the scaler and the LCD panel. The LVDS transmitter converts the parallel (24 or 48-bit) digital data stream generated by the scaler into serial data on the LVDS bus. The LVDS transmitter is a general-purpose chip that can be used in any monitor. This circuit design, with an external LVDS transmitter, is also typical, to a greater extent, for higher-class monitors, because they use specialized scalers with fewer additional functions. An example of a block diagram of a monitor with similar circuitry is shown in Fig. 9. As an example of a monitor with this design, we can name the model LG FLATRON L1811B.

Fig.9

Here, only the basic options of modern circuit design were considered, although in the whole variety of models and brands of LCD monitors you can find the most various combinations presented block diagrams. Summary Table 1 shows the types of chips used and the circuit design features of the most popular models of LG monitors.

Table 1. Features of the circuitry of LG TFT monitors

|

Monitor model |

Layout option |

Circuit design option |

Types of main chips |

Type used LCDpanels |

||

|

CPU |

Scaler |

LVDS |

||||

|

L1510S |

see fig.1 |

see fig.6 |

MTV312 |

MST9011 |

LM150X06-A3M1 |

|

|

L1510P |

see fig.1 |

see fig.6 |

MTV312 |

MST9051 |

LM150X06-A3M1 |

|

|

L1511S |

see fig.1 |

see fig.9 |

MTV312 |

GMZAN2 |

THC63LVDM83R |

1) LM150X06-A3M1 2) LM150X07-B4 |

|

L1520B |

see fig.1 |

see fig.6 |

MTV312 |

MST9011 |

LM150X06-A4C3 |

|

|

L1710S |

see fig.1 |

see fig.8 |

GM2121 |

1) HT17E12-100 2) M170EN05 |

||

|

L1710B

|

see fig.1 |

see fig.6 |

MTV312 |

MST9151 |

1) LM170E01-A4 2) HT17E12-100 3) M170EN05V1 |

|

|

L1715 /16 S |

see fig.1 |

see fig.6 |

MTV312 |

MST9111 |

LM170E01-A4 |

|

|

L1720B |

see fig.1 |

see fig.6 |

MTV312 |

MST9111 |

1) LM170E01-A4 2) LM170E01-A5K6 3) LM170E01-A4K4 4) LM170E01-A5 |

|

|

L1730B |

see fig.1 |

see fig.8 |

GM5221 |

1) LM170E01-A5K6 2) LM170E01-A5N5 3) LM170E01-A5KM |

||

|

L1810B |

see fig.3 |

see fig.6 |

MTV312 |

MST9151 |

1) LM181E06-A4M1 2) LM181E06-A4C3 |

|

|

L1811B |

see fig.3 |

see fig.9 |

68HC08 |

GM5020 |

THC63LVD823 |

1) LM181E05-C4M1 2) LM181E05-C3M1 |

|

L1910PL |

see fig.1 |

see fig.6 |

MTV312 |

MST9151 |

FLC48SXC8V-10 |

|

|

L1910PM |

see fig.1 |

see fig.6 |

MTV312 |

MST9151 |

FLC48SXC8V-10 |

|

An analytical review of the data presented in Table 1 allows several interesting conclusions to be drawn.

Firstly, almost all of the monitors presented in Table 1 have the same layout, which, by the way, is typical for almost all modern monitors, regardless of the manufacturer.

Secondly, LG uses mainly a microcontroller as a control processor in its monitors MTV312 , developed by the company MYSON TECHNOLOGY. This microcontroller is based on the famous microprocessor 8051. In addition, the microcontroller includes RAM, Flash ROM, ADC, clock processor, digital ports and a whole series other elements.

Thirdly, It should be noted that some monitor models may use various types LCD panels. For example, under the cover of monitors sold under the brand name FLATRON 1710B, you can find three different types of LCD panels: LM170E01-A4, HT17E12-100, M170EN05V1, and this is a very common practice of almost all monitor manufacturers. But an interesting fact is that sometimes LG uses panels from other manufacturers in its monitors, being the world's largest manufacturer of them. The ownership of an LCD panel can be determined by its marking, the first letters of which identify the manufacturer:

L.M.– production panels LG-PHILIPS

HT– production panels HITACHI

M– production panels AUO

FLC– production panels FUJITSU

LCD display is the most common type of TV and monitor screens, as well as phone displays and other devices. Such a spread this type screen received thanks to a number of undeniable advantages.

In order to understand all the positive qualities of LCD displays, you should understand what it is, as well as know the operating principle and design of such screens. This is exactly what this article will discuss.

1. Decoding LCD

LCD display means liquid crystal screen, if translated into English language- Liquid crystal display. It follows from this that LCD and LCD are one and the same. This technology received its name due to the use of a unique substance that is always in a liquid state and has optical properties inherent in crystals.

A modern LCD screen has a number of advantages that are provided precisely by liquid crystals. The permanent liquid state of liquid crystal molecules makes it possible to control their optical properties by influencing them with electricity. In this case, the molecules change their location, refracting the passing light at the desired angle, filtering out a certain spectrum of radiation.

2. LCD display device

Almost all LCD displays that exist today have an identical design. If we talk about design, then any LCD monitor or TV consists of the following components:

- LCD matrices;

- Light source;

- Contact harness;

- Frame (body).

The LCD matrix consists of two glass plates, between which there is a thin layer of liquid crystals. Essentially, it is an array consisting of a huge number of cells called pixels. Each pixel of the matrix consists of several liquid crystal molecules and two polarizing filters. Moreover, the planes of these filters are located perpendicular to each other.

Each pixel of the matrix is located between two special transparent electrodes, which makes it possible to control the location of molecules in each pixel separately. LCD technology can be based on the transmission or reflection of light, depending on the monitor device, through liquid crystal molecules. There is practically no difference between these types of matrices. However, it is worth noting that most LCD displays work by passing light through a layer of liquid crystals.

3. Operating principle of LCD display

The operating principle of an LCD display is that, in the absence of liquid crystal molecules, light is transmitted by the first polarizing filter and completely blocked by the second.

The liquid crystals themselves are located between these filters in such a way as to refract light passing through the first filter so that it passes unhindered through the second. This is how TN matrices are designed. Liquid crystal displays with other types of matrices can operate in the opposite way, but the operating principle does not change. That is, in a calm state, the radiation is blocked and does not pass through the matrix, and when the electromagnetic field is excited, the radiation plane changes so that the light passes without obstacles

In order for the molecules of liquid crystals to be arranged in the desired order without exposure to electricity, special microscopic grooves are applied to the contacting surface of the electrodes, arranging the molecules in the desired order. Thus, if certain areas of the matrix are affected, an image is obtained.

Every modern LCD screen has a high resolution. This means that the matrix consists of a huge number of pixels, and each of them can be controlled individually. In other words, if you enlarge any area of the screen, you can notice small cells; by changing the voltage of each of these cells, you can change the angle of refraction of light at that particular point. By creating the required voltage in each of the cells, a specific image is created.

4. Type of LCD matrix backlight

Modern LCD displays can use two backlight options:

- Fluorescent lamps;

- LED backlight.

Of course, the type of backlight significantly affects image quality. Fluorescent lamps are considered an outdated lighting method. The main problem of this type of backlight is the impossibility of uniformly distributing light across the entire plane of the screen, which does not allow achieving high image quality. It was used in the first LCD matrices and is becoming less common today.

Light Emitting Diode (LED) backlighting, better known as LED, is the latest development that allows for higher image quality. This type of lighting has a number of advantages.

Firstly, it is low energy consumption. Secondly, LED backlight emits more intense light, which allows the radiation to be distributed more evenly. Thanks to its compact size, this backlight does not take up much space, which allows you to make screens even thinner.

5. Types of LCD matrices

There are several types of LCD matrices in the world, but only two types are found on the domestic market:

- TN+Film;

Both options have fairly high performance. If we talk about which option is better to choose, it should be noted that more and more manufacturers are giving preference to IPS matrices, as they allow for more natural colors to be conveyed.

Of course, like any other technology, there are also pros and cons. IPS matrices are distinguished by excellent image quality, high clarity and excellent color rendition. However, they have a slow response. Modern technologies allowed us to improve this indicator to a high level.

TN+Film matrices are inferior in image quality and clarity. However, they have a fast response, which allows such monitors to display the most vivid special effects and quick videos records. However, it is worth understanding that all these measurements are carried out using special equipment. At home, you are unlikely to notice a significant difference between these matrices. Therefore, the choice is yours.

6. TFT display device: Video

Of course, knowing all these nuances, people who process photographs prefer IPS matrices, since they do not require fast response, but at the same time they need the most natural color rendition. In other cases, the type of matrix does not matter.

And, of course, all characteristics depend on the manufacturer, as well as on the technology and materials used. You should not think that all IPS matrices are the same; they can also differ from each other. It is worth understanding that the more expensive the monitor (or TV), the higher image quality you can get. The same can be said about TN+Film matrices.

Whatever LCD display you choose, you should definitely familiarize yourself with its capabilities and technical characteristics. Today, LCD displays are the most common for a number of reasons. You already know their advantages. Thanks to this, they are direct competitors to plasma panels, but at the same time they have a lower cost, which makes them more accessible to users. In addition, they have a greater resource. In other words, the LCD display lasts significantly longer than the plasma panel.